Two-component foaming machine

Key words:

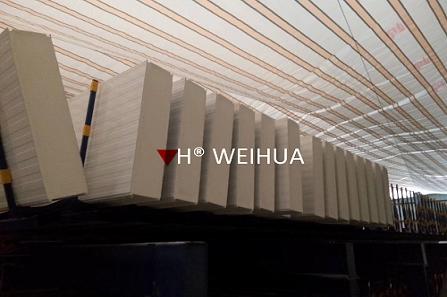

Continuous sandwich panel production line, metal curtain wall composite panel

Classification:

Product Description

1. Introduction:

WH-PU-2-40 two-component continuous high-pressure foaming machine adopts two-component foaming system, 1 polyether (polyester) and 2 isocyanate, each component is measured separately, and the flow rate is controlled in closed loop. Using frequency converter, high-precision volume flowmeter and magnetic coupling, the system can automatically change the output flow rate and mixing ratio instantaneously. The working mode of the system is continuous on-line mixing. The polyether is fed to the dynamic mixer through respective metering units for high-speed mixing. In order to improve the foaming effect and make the mixed polyether fully blend into the foaming nucleation gas, we adopt a group of gas metering devices and stir at high speed to make the mixed polyether fully nucleate and emulsify. The output mixed polyether is sprayed into mist form through the damping hole of the mixing head through the high-precision high-pressure metering unit, then it is micromixed with high-pressure mist of isocyanate. The whole machine adopts man-machine interface control, animation display work flow, various process parameters, including component flow rate, mixing ratio and mixing mode, can be set and modified in the panel, the electronic control system and the production line part are provided with signal communication interface, when the production line changes speed, the various material flow rate of the foaming machine is also changed in the same proportion, so as to ensure the quality stability of the composite board and realize the online automatic production of the whole line.

2. Technology:

With the popularization and application of high flame retardant PIR B1 grade polyurethane, pentane is put into use as a foaming agent, and the new foaming machine will become the core configuration of the production line. After nearly two decades of continuous development and optimization of the foaming machine, Weihua has now fully mastered all the core technologies and has been successfully applied to many production lines at home and abroad. These technologies include:

Flow control technology:

Temperature control technology:

self cleaning gun head technology:

high speed shear mixing emulsification technology:

3. Technical parameters

1) 1) Unit pouring quantity: 120-500 g/s;

4. foaming performance

The foaming performance of the finished board is quite good. The following figure is a cold storage sandwich panel with a thickness of 250mm and a fire rating of B2. The enclosed area percentage is high and the thermal conductivity is low.

Weihua Machinery

Related Products

Product inquiry

Language

Language