Five-component foaming machine

Overview WH-PU-5-80 type continuous sheet foaming machine mainly solves PUR/PIR foaming. The main parts of the equipment are all imported, the material ratio is adjustable online, the performance is stable, the operation is simple, and the production efficiency is high. The raw materials used in this machine are mainly dry white material, MDI polyester, catalyst 1, catalyst 2, foaming agent 1 and gas nucleating agent. The dry white material and each component are premixed in advance through high-speed shearing and emulsification, then the combined polyether is output through a high-pressure metering system, and the black material from another group of high-pressure metering systems collides in the gun head to realize continuous foaming. Design of gun head: gun head adopts self-cleaning gun head flow ratio control technology with loop: temperature control technology: self-cleaning gun head technology: high-speed shear mixing emulsification technology: technical parameters: 4) spray pressure range of pouring head: 8-18Mpa, rated 15Mpa;5) Pouring head pressure adjustment: pneumatic, online adjustment during production; 6) Flow rate of each component (adjustable mixing ratio): B) Polyol (polyol):50~320 g/s f) isocyanate: 60~600 g/s; G) catalyst 1:1.5-15 g/s; H) catalyst 2:1.5-15 g/s; I) n-pentane blowing agent: 5-35 g/s

Key words:

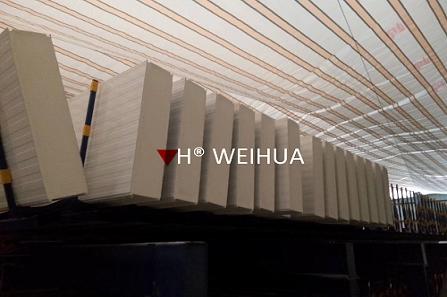

Continuous sandwich panel production line, metal curtain wall composite panel

Classification:

Product Description

Overview

WH-PU-5-80 continuous sheet foaming machine mainly solves PUR/PIR foaming. The main parts of the equipment are all imported, the material ratio is adjustable online, the performance is stable, the operation is simple, and the production efficiency is high. The raw materials used in this machine are mainly dry white material, MDI polyester, catalyst 1, catalyst 2, foaming agent 1 and gas nucleating agent. The dry white material and each component are premixed in advance through high-speed shearing and emulsification, then the combined polyether is output through a high-pressure metering system, and the black material from another group of high-pressure metering systems collides in the gun head to realize continuous foaming.

The design of the gun head: the gun head adopts a self-cleaning gun head with a loop

proportional flow control technology:

Temperature control technology:

self cleaning gun head technology:

high speed shear mixing emulsification technology:

Technical parameters:

4) Spray pressure range of pouring head: 8-18Mpa, rated 15Mpa;

5) Pressure adjustment of pouring head: pneumatic and on-line adjustment during production;

6) Flow rate of each component (mixing ratio adjustable):

B) Polyol (polyol):50~320 g/s

f) Isocyanate: 60~600 g/s;

g) Catalyst 1:1.5-15 g/s;

h) Catalyst 2:1.5-15 g/s;

I) n-pentane pentane blowing agent: 5-35 g/s

5) Pressure adjustment of pouring head: pneumatic and on-line adjustment during production;

6) Flow rate of each component (mixing ratio adjustable):

B) Polyol (polyol):50~320 g/s

f) Isocyanate: 60~600 g/s;

g) Catalyst 1:1.5-15 g/s;

h) Catalyst 2:1.5-15 g/s;

I) n-pentane pentane blowing agent: 5-35 g/s

pentane system

Under the Montreal Protocol on Substances that Deplete the Ozone Layer, published in 1989, the use of chlorofluorocarbons has been discontinued in Europe and the Americas. Since 1993, cyclopentane has been considered in Europe as an alternative to chlorofluorocarbons. Currently, China, India, the United Arab Emirates and other developing countries are phasing out CFCs/HCFCs. For the foaming system with pentane as foaming agent, the following factors need to be considered:

7. Pentane storage system

The pentane storage and conveying system is mainly used to store cyclopentane unloaded from the tanker and automatically feed the foaming machine. Because pentane vapor is flammable and explosive, the system must be strictly in accordance with the relevant standards.

The pentane storage system includes: tank body, pentane delivery system, tank body breathing system, liquid level system, unloading system and pentane detection system.

8. Pentane foaming system

All pentane related parts and pipes on the foaming machine are installed in a small room with probes and dual exhaust systems to ensure safety. The detection head is installed on the storage tank.

The safety system is controlled by an independent electrical cabinet, independent of the operating cabinet.

9. Pentane safety system

Pentane detection devices will be installed in pentane leakage areas and possible leakage areas, including crawler and cloth areas and storage tanks. Help customers run production lines safely and reliably.

Main Achievements

WEIHUA is the only Chinese company that has won the bid for the United Nations pentane continuous foaming machine project (refer to the winning documents). We have mastered pentane storage, transportation, mixing, safety and other technologies, and put into actual production in 2014. We not only provide equipment, but also provide customers with a series of services such as establishing employee training mechanism, operating procedures, post leakage early warning mechanism, etc., to achieve 100 percent safety from machine to personnel.

WEIHUA's latest product: four-component foaming machine for polyurethane sandwich panel production line, delivered to Duowei Group, a leading domestic sandwich panel manufacturer. The flow accuracy of MDI is 1 ‰, the mixture is 1 ‰, the catalyst is 1 ‰, and the foaming agent is 5 ‰.

Weihua Machinery

Related Products

Product inquiry

Language

Language