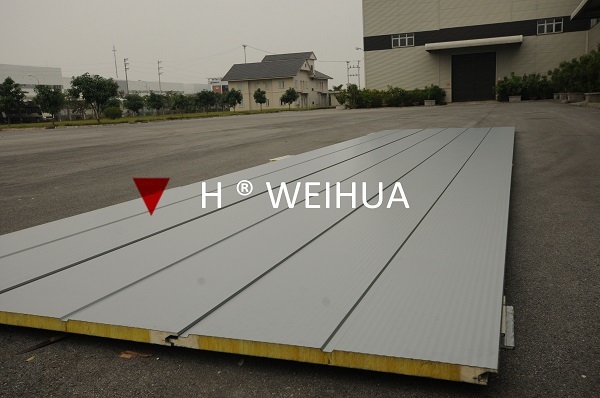

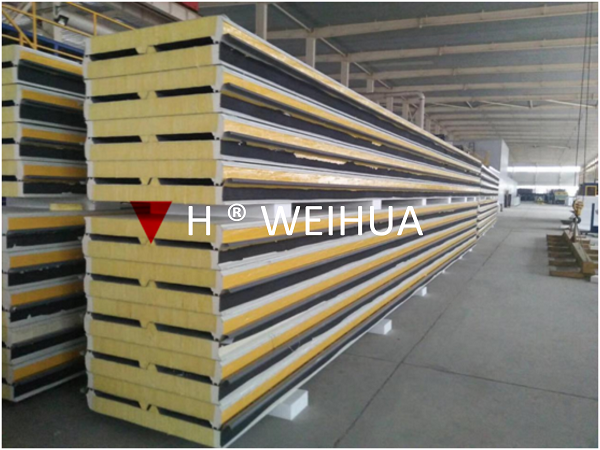

Rock wool system

Key words:

Continuous sandwich panel production line, metal curtain wall composite panel

Classification:

Product Description

The rock wool system is to change the fiber direction (horizontal into vertical silk) by slitting, transporting and turning the large pieces of rock wool with horizontal tiling fibers, so as to increase the bearing strength of the finished rock wool composite board, so as to meet the requirements of the strength of the building composite board. Then the rock wool strips are reasonably arranged cross each other to avoid the weak link of fault concentration in the longitudinal butt joint of the rock wool strips, and a high-strength composite board product is obtained. The arranged rock wool strips are cut, milled on the lap surface, sprayed with upper and lower rock wool, and finally bonded and solidified with upper and lower color steel plates, glass fiber cloth, calcium silicate board and other materials to form an integral composite board. Rock wool is composed of storage hoist, rock wool slitting machine, steering conveyor, plate copying and turning vertical silk machine, rock wool typesetting and feeding machine, edge milling machine, rock wool glue spraying machine, dust suction machine and other equipment.

Weihua Machinery

Related Products

Product inquiry

Language

Language